WIRELESS EBIKE BATTERY CHARGER

Category : INDUSTRIAL PROJECTS

Wireless Resonant Inductive Power Transfer for an Ebike Charging Battery

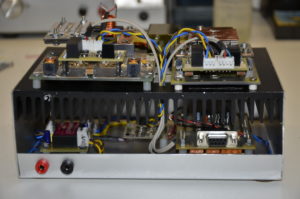

In this page RubinoLab.com presents the prototype and experimental tests of an E-bike 300W battery charger for a cyclo-station based on wireless power technology made for research.

For this project, several scientific papers were written with a mathematical model developed and conducted with performance analysis to determine the voltage transfer function, maximum power transfer capacity, efficiency for different air gaps (1 -3 cm) and misalignments (0.5-1.5 cm).

The resonance frequency of this circuit for wireless charging batteries is 40kHz.

To achieve maximum efficiency and maximum power transfer, work at the resonance frequency.

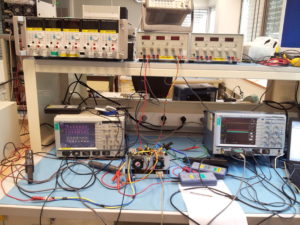

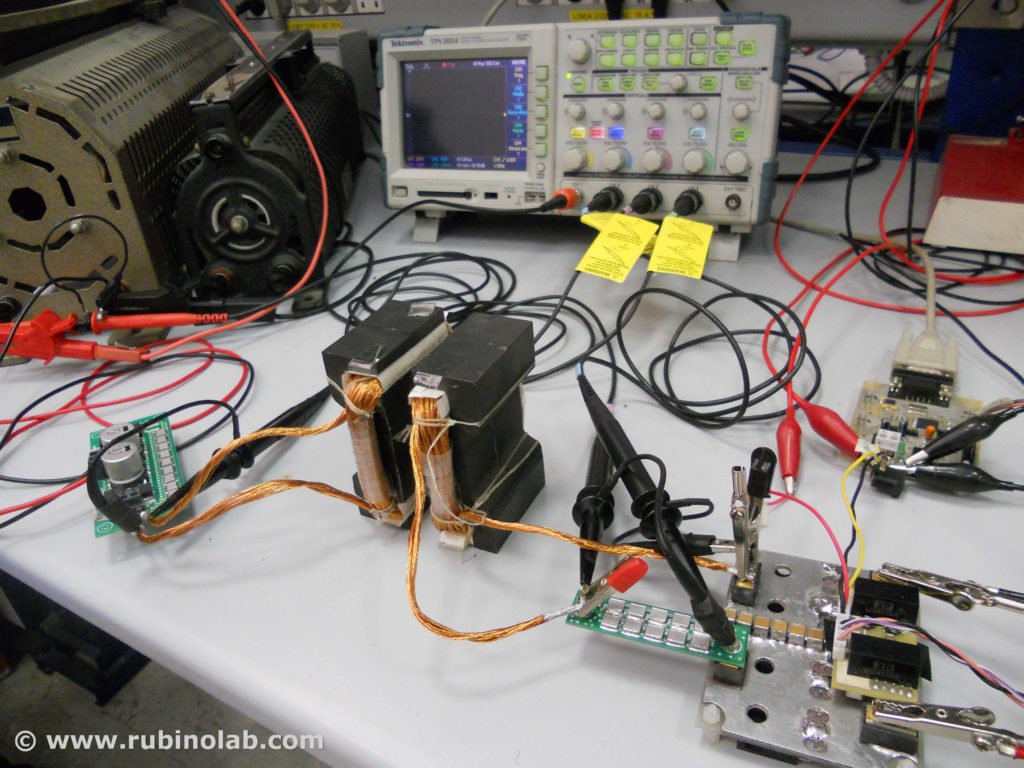

To evaluate the correctness of the circuit a LabView panel was realized where it was possible to characterize the circuit by varying the frequency between 30-50 kHz on the prototype.

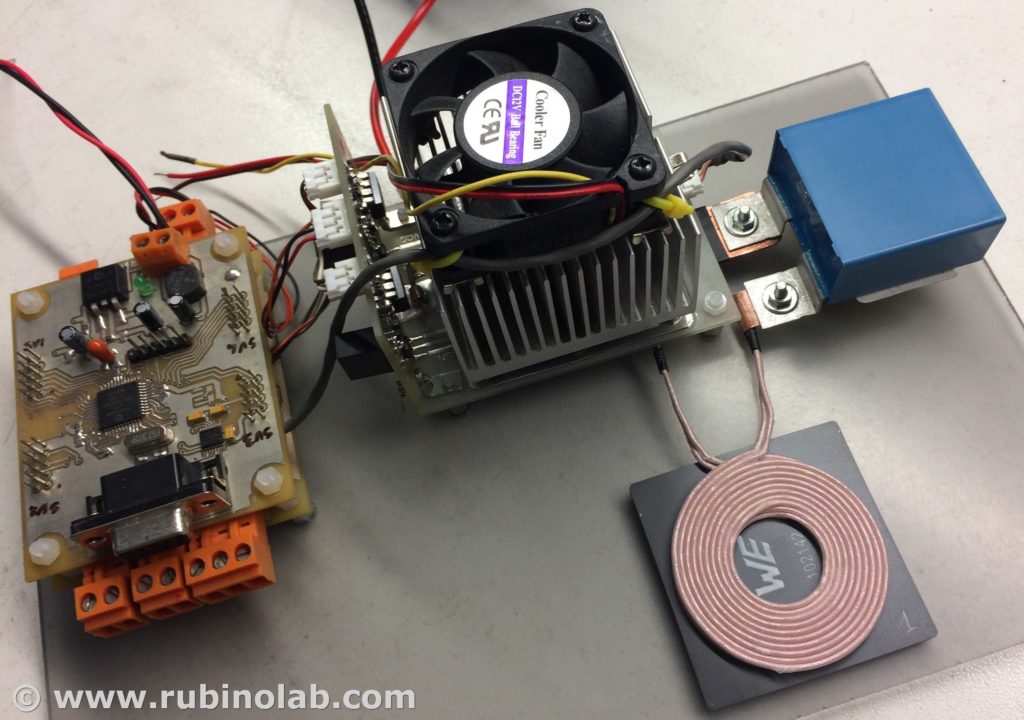

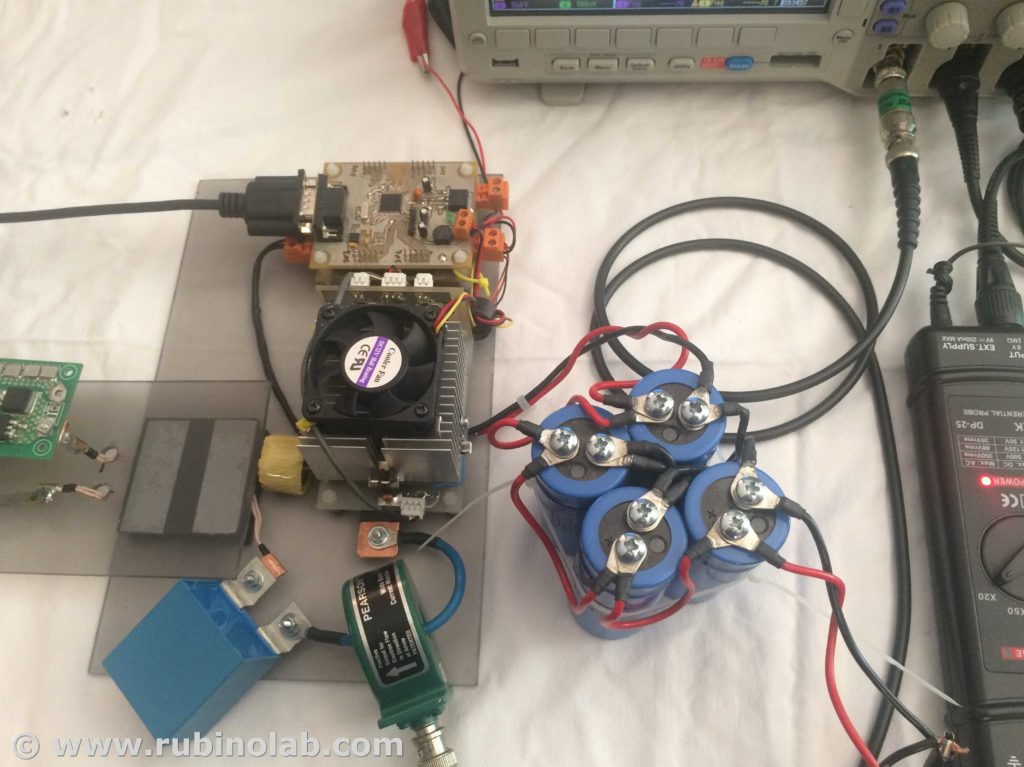

This is a second prototype of the Ebike Charging battery. It is a primary part of the charger. it works at a higher frequency and for the magnetic part has been used a coil of Wurth Elektronik.

The circuit during the tests connected to the electronic instrumentation.

Scientific papers:

1- Resonant inductive power transfer for an E-bike charging station (Journal ELSEVIER)